Understanding Invention Prototypes

An invention prototype is a preliminary working model of your invention that demonstrates its functionality, design, and potential value. It serves as a tangible representation of your concept, allowing you to test, refine, and present your ideas to others. Whether crafted from basic materials or developed using advanced manufacturing techniques, a prototype bridges the gap between conceptual design and final product.

What Is an Invention Prototype

At its core, an invention prototype is a three-dimensional proof of concept that brings your invention to life. Unlike sketches or digital renderings, a prototype provides a physical manifestation that you can touch, test, and demonstrate. Prototypes range from simple mock-ups that illustrate basic form and function to sophisticated working models that closely resemble the final product. They serve as essential tools for testing assumptions, identifying design flaws, and gathering valuable feedback before investing in full-scale production.

The Role of Prototypes in the Innovation Process

Prototypes play multiple crucial roles throughout the innovation journey. In the early stages, they help validate technical feasibility and identify potential challenges. As development progresses, prototypes facilitate iterative improvements by allowing inventors to test different approaches and refinements. They also serve as powerful communication tools, helping inventors explain their concepts to manufacturers, investors, and potential customers.

During the innovation process, prototypes help:

- Validate technical assumptions and identify engineering challenges

- Test user interaction and ergonomics

- Demonstrate market viability to stakeholders

- Secure patent protection by proving reduction to practice

- Gather user feedback for product refinement

- Estimate manufacturing costs and requirements

Different Types of Prototypes

Inventors typically develop several types of prototypes as their invention evolves:

Proof of Concept Prototypes focus on demonstrating the core functionality of your invention. These basic models may look nothing like the final product but prove that your fundamental idea works. They’re typically rough, quick to produce, and inexpensive.

Visual Prototypes emphasize appearance over function. These models showcase the invention’s design, proportions, and aesthetic features. They’re particularly useful for gathering feedback on form factor and user interface elements.

Working Prototypes combine both form and function, closely resembling the final product in appearance and operation. These sophisticated models demonstrate how the invention will work in real-world conditions and are often used for final testing and investor presentations.

Manufacturing Prototypes serve as references for production. They incorporate specific materials and manufacturing processes planned for mass production, helping identify potential manufacturing challenges and optimize production costs.

Why Every Inventor Needs a Prototype

Creating a prototype is an essential step in the invention process for several compelling reasons:

Risk Reduction: Prototypes help identify and resolve technical issues early, when changes are less expensive and easier to implement. They allow inventors to test different approaches and materials before committing to final design decisions.

Patent Protection: A working prototype can strengthen patent applications by demonstrating reduction to practice. It provides concrete evidence of how your invention works and helps distinguish it from existing products.

Investor Attraction: Investors and licensees often require working prototypes before committing resources. A well-executed prototype demonstrates market readiness and reduces perceived risk, making your invention more attractive to potential partners.

Market Validation: Prototypes enable real-world testing with potential customers. This feedback is invaluable for refining features, improving usability, and confirming market demand before launching full production.

Manufacturing Planning: Physical prototypes help identify production requirements, material costs, and potential manufacturing challenges. This information is crucial for accurate cost estimation and production planning.

Planning Your Prototype Development

Before diving into prototype creation, careful planning helps ensure efficient use of resources and successful development. A well-structured plan guides your prototype development process, keeping you focused on essential goals while managing time and budget effectively.

Setting Clear Objectives

Establishing specific, measurable objectives for your prototype development is crucial for success. Each objective should directly support your invention’s path to market while addressing key technical and business requirements.

Key objectives typically include:

- Demonstrating core functionality and technical feasibility

- Testing specific features or mechanisms

- Validating ergonomics and user interaction

- Exploring manufacturing methods and materials

- Creating presentation models for investors or licensees

Document your objectives in order of priority, as this helps guide resource allocation and development sequencing. Each objective should include specific success criteria that define when that aspect of development is complete.

Determining Your Prototype’s Purpose and Audience

Different audiences require different types of prototypes, and understanding your primary audience helps focus development efforts appropriately:

Technical Validation: Engineers and technical experts need prototypes that demonstrate mechanical function, electrical systems, or software operations. These prototypes focus on performance metrics and technical specifications.

User Testing: End-users require prototypes that simulate the actual user experience. These models should closely match intended ergonomics and interface designs, even if using substitute materials or simplified mechanisms.

Investor Presentations: Investors typically want to see prototypes that demonstrate market readiness and manufacturing feasibility. These models should balance functionality with professional appearance and production practicality.

Manufacturing Partners: Manufacturers need prototypes that clearly show assembly requirements, material specifications, and production processes. These prototypes should incorporate intended production materials whenever possible.

Budgeting for Prototype Development

Effective prototype budgeting requires consideration of multiple cost factors:

Materials and Components:

- Raw materials for structural elements

- Specialized components and electronics

- Fasteners and assembly materials

- Backup materials for iterations

Development Tools:

- Design software licenses

- Fabrication equipment or services

- Testing equipment

- Safety equipment and workspace setup

Professional Services:

- Engineering consultation

- Industrial design

- Specialized fabrication

- Testing and certification

Contingency Planning:

- Reserve 20-30% of your budget for unexpected challenges

- Account for multiple iterations and refinements

- Include costs for design changes and improvements

- Budget for protecting intellectual property

Creating a Prototype Development Timeline

A realistic timeline helps manage expectations and maintain progress. Break your development process into distinct phases:

Phase 1: Research and Planning (2-4 weeks)

- Market research and competitive analysis

- Technical feasibility studies

- Material and component sourcing

- Development team assembly

Phase 2: Initial Design (4-8 weeks)

- Concept sketches and refinement

- CAD modeling and technical drawings

- Material and process selection

- Preliminary cost analysis

Phase 3: First Prototype (6-12 weeks)

- Component procurement

- Basic assembly and testing

- Functional validation

- Initial feedback gathering

Phase 4: Refinement (8-16 weeks)

- Design modifications based on testing

- Secondary prototypes

- User testing and feedback

- Manufacturing consultation

Phase 5: Final Prototype (4-8 weeks)

- Production-ready design

- Final assembly and testing

- Documentation completion

- Presentation preparation

Important Timeline Considerations:

- Include buffer time for unexpected challenges

- Account for supplier lead times

- Plan for multiple iteration cycles

- Consider seasonal impacts on testing or presentation

- Allow time for patent filings if needed

Building in flexibility is crucial, as prototype development often uncovers unexpected challenges or opportunities that require timeline adjustments. Regular progress reviews help identify potential delays early, allowing for proactive schedule management.

Remember that rushing prototype development often leads to costly mistakes or missed opportunities for improvement. A well-planned timeline balances the urgency of market opportunity with the need for thorough development and testing.

The Prototype Development Process

The journey from concept to working prototype follows a structured development process that helps transform ideas into tangible, functional inventions. Each stage builds upon previous work, creating a comprehensive foundation for your final prototype.

Initial Sketches and Design Documentation

The development process begins with thorough documentation of your invention concept. This crucial first step creates a clear roadmap for prototype development.

Concept Sketching

- Start with rough sketches exploring different design approaches

- Include multiple views (front, side, top) showing key features

- Add dimensions and scale references

- Note important functional elements and mechanisms

Technical Documentation

- Create detailed technical drawings with precise measurements

- Document component relationships and assembly sequences

- Specify critical dimensions and tolerances

- Include electrical schematics or flow diagrams if applicable

- Note special features or unique mechanisms

Design Requirements

- List essential functions and features

- Define performance specifications

- Document size and weight constraints

- Specify user interface requirements

- Note environmental conditions and durability needs

Choosing Materials and Components

Selecting appropriate materials and components significantly impacts prototype performance, cost, and development time.

Material Selection Criteria

- Functional requirements (strength, flexibility, durability)

- Cost and availability

- Manufacturability

- Environmental considerations

- Safety requirements

- Aesthetic properties

Component Sourcing

- Identify standard versus custom components

- Research supplier options and lead times

- Compare cost-quality trade-offs

- Consider minimum order quantities

- Evaluate alternative components for testing

Material Testing

- Conduct small-scale material tests

- Verify material properties

- Test compatibility between different materials

- Evaluate finishing options

- Document material performance characteristics

Proof of Concept Models

Proof of concept models validate core functionality before investing in more detailed prototypes.

Basic Functional Testing

- Build simple working models of critical mechanisms

- Test fundamental principles

- Verify basic functionality

- Identify potential design issues

- Document performance results

Design Validation

- Confirm technical feasibility

- Test mechanical principles

- Verify electrical systems

- Evaluate software functionality

- Document design changes needed

Working Prototype Development

Working prototypes combine validated concepts into fully functional models that closely represent the final product.

Assembly Process

- Create detailed assembly procedures

- Document component integration

- Build subsystems separately when possible

- Test assemblies at each stage

- Maintain quality control documentation

Integration Testing

- Combine subsystems systematically

- Test interactions between components

- Verify overall functionality

- Document integration challenges

- Address interface issues

Refinement

- Optimize component placement

- Improve assembly efficiency

- Enhance user interface elements

- Reduce complexity where possible

- Document all modifications

Testing and Iteration

Systematic testing and refinement ensure the prototype meets all requirements and performs reliably.

Performance Testing

- Develop comprehensive test protocols

- Measure key performance metrics

- Document test results

- Compare against specifications

- Identify areas for improvement

User Testing

- Create user testing scenarios

- Gather feedback from potential users

- Document user interactions

- Identify usability issues

- Collect improvement suggestions

Iteration Process

- Analyze test results

- Prioritize improvements

- Implement design changes

- Verify modifications

- Document all iterations

Final Documentation

- Update technical drawings

- Record final specifications

- Document assembly procedures

- Create maintenance instructions

- Prepare user manuals

Throughout the development process, maintain detailed records of:

- Design decisions and rationale

- Test results and observations

- Material and component specifications

- Assembly procedures and challenges

- Cost information and supplier details

- User feedback and suggestions

- Performance data and metrics

- Quality control measures

This comprehensive documentation proves invaluable for patent applications, manufacturing planning, and future product improvements. The prototype development process often requires multiple iterations, with each cycle bringing the invention closer to its final form.

Prototype Creation Methods

The method you choose for creating your prototype significantly impacts development time, cost, and functionality. Each approach offers unique advantages and limitations, making them suitable for different stages of prototype development and various types of inventions.

Traditional Hand-Built Prototypes

Traditional hand-built prototyping remains a valuable approach, particularly in the early stages of development. This method involves crafting prototypes using basic tools, readily available materials, and manual fabrication techniques. Inventors often start with materials like wood, plastic sheets, metal stock, or existing components modified to suit their needs.

Hand-built prototypes excel at proving basic concepts quickly and cost-effectively. They allow for rapid modifications during testing and don’t require specialized equipment or technical expertise. This approach proves particularly useful for mechanical devices, furniture designs, and consumer products where form and function can be tested with basic materials.

The process typically begins with gathering appropriate materials and tools, followed by careful measurement and marking. Components are then cut, shaped, and assembled according to design specifications. While this method may not produce the most polished results, it offers immediate feedback and allows for quick iterations during the early development phase.

3D Printing and Rapid Prototyping

3D printing has revolutionized prototype development by enabling the creation of complex geometries with unprecedented speed and accuracy. This additive manufacturing process builds objects layer by layer from digital designs, offering remarkable flexibility in materials and structures.

Common 3D printing technologies include:

Fused Deposition Modeling (FDM) uses thermoplastic filaments to build objects layer by layer. This technology offers good structural strength and works well for functional prototypes. Materials range from basic PLA and ABS to engineering-grade polymers with specific properties.

Stereolithography (SLA) employs liquid resin cured by UV light, producing highly detailed parts with smooth surface finishes. This method excels at creating precise visual prototypes and complex geometries but may sacrifice some structural strength.

Selective Laser Sintering (SLS) fuses powder materials with a laser, creating strong, functional parts. This technology works well for complex mechanical components and can utilize various materials, including plastics, metals, and ceramics.

CNC Machining

Computer Numerical Control (CNC) machining offers precision fabrication for prototype components. This subtractive manufacturing process removes material from solid blocks to create finished parts according to digital designs. CNC machining excels at producing metal components with tight tolerances and excellent surface finishes.

The process begins with creating detailed CAD models, which are converted into machine instructions through CAM software. Modern CNC machines can perform multiple operations automatically, including milling, turning, drilling, and threading. This technology proves particularly valuable for creating functional prototypes that require high strength, precise dimensions, or specific material properties.

CNC machining particularly suits prototypes requiring:

- High dimensional accuracy

- Excellent surface finish

- Strong mechanical properties

- Production-grade materials

- Complex internal features

- High repeatability

Professional Prototype Development Services

Professional prototype development services offer comprehensive solutions for inventors who need specialized expertise or capabilities. These services combine multiple fabrication methods with design expertise and project management to create sophisticated prototypes.

These firms typically provide end-to-end support, beginning with design review and optimization. They can suggest appropriate materials and manufacturing methods based on your requirements and budget. Many offer additional services such as design for manufacturing analysis, cost optimization, and preparation for mass production.

Professional services particularly benefit complex inventions requiring:

- Multiple fabrication technologies

- Specialized materials or processes

- Electronic integration

- Advanced finishing techniques

- Regulatory compliance testing

- Manufacturing scalability analysis

Working with professional services often includes access to industrial-grade equipment and expertise that would be impractical for individual inventors to maintain. They can also provide valuable insights into manufacturing processes and help prepare your invention for production.

Selection of a prototyping method should consider:

- Required accuracy and finish quality

- Material properties needed

- Time constraints

- Budget limitations

- Quantity required

- Future production methods

- Technical complexity

- Available expertise

Most successful prototype development projects utilize a combination of these methods, selecting the most appropriate approach for each component or development stage. This hybrid approach often provides the optimal balance of cost, time, and functionality while maintaining flexibility throughout the development process.

Testing and Evaluating Your Prototype

Establishing Testing Criteria

Testing criteria form the foundation of meaningful prototype evaluation. Begin by developing specific, measurable performance standards that align with your invention’s intended purpose and market requirements. These criteria should encompass functional requirements, safety standards, durability expectations, and user experience metrics.

Create a comprehensive testing plan that defines exact parameters for success. For mechanical devices, this might include load limits, operational speed, or durability cycles. For electronic products, testing criteria often focus on power consumption, heat generation, and response times. Consumer products require additional criteria related to ease of use, comfort, and aesthetic appeal.

Include environmental factors in your testing criteria, considering how your prototype performs under various conditions. This might involve temperature ranges, humidity levels, or exposure to specific substances. If your invention must meet industry standards or regulatory requirements, incorporate these specifications into your testing criteria.

Conducting User Testing

User testing provides crucial insights into how your invention performs in real-world conditions. Start by identifying your target user group and creating realistic usage scenarios. Select test participants who represent your intended market, considering factors like age, experience level, and specific needs.

Structure your user testing sessions to gather both quantitative and qualitative data. Begin with a brief orientation that explains the basic function without revealing too much about intended use. This allows you to observe natural interactions and discover potential uses or problems you hadn’t considered. Record time-on-task measurements, success rates, and error frequencies.

Create specific tasks for users to complete, ensuring these tasks represent typical use cases for your invention. Observe users as they interact with your prototype, noting any confusion, hesitation, or unexpected behavior. Pay particular attention to ergonomic factors, such as comfort during extended use or ease of handling.

Gathering and Implementing Feedback

Feedback collection requires systematic organization and analysis. Develop feedback forms that capture both structured responses and open-ended observations. Use rating scales for quantifiable aspects like ease of use or satisfaction levels, while allowing space for detailed comments about specific features or concerns.

Analyze feedback methodically, looking for patterns and common themes. Categorize feedback into areas such as functionality, usability, aesthetics, and potential improvements. Prioritize issues based on frequency of occurrence and severity of impact. Create action items for addressing critical concerns while maintaining a log of suggested improvements for future iterations.

Implementation of feedback should follow a structured process. Begin with critical functional issues that affect core performance or safety. Move on to usability improvements that significantly impact user experience. Consider aesthetic changes last, unless they directly affect functionality or user adoption.

Documentation and Record Keeping

Maintain detailed records throughout the testing process to support future development and potential patent applications. Create a digital repository for all test data, user feedback, and performance measurements. Include photographs or videos documenting testing procedures and user interactions.

Your documentation should capture:

- The complete testing environment and conditions

- Detailed test procedures and methodologies

- Raw data from all performance measurements

- User demographics and testing scenarios

- Observed failures or issues

- Solutions implemented and their effectiveness

- Changes made to the prototype design

- Impact of modifications on performance

Organize documentation chronologically while maintaining cross-references between related tests and modifications. This creates a clear development timeline that proves invaluable for patent applications and future improvements. Include annotations explaining the rationale behind design changes and their outcomes.

Keep separate sections for different types of testing results. Technical performance data should be organized separately from user feedback, though with clear links between related findings. Maintain version control for your prototype iterations, with each version clearly documented and linked to specific test results and modifications.

Your record-keeping system should facilitate easy retrieval of specific information while maintaining the security of sensitive data. Consider using a combination of cloud storage and local backups to protect your documentation. Regular updates to your records ensure nothing is lost or forgotten during the development process.

This comprehensive approach to testing and evaluation provides a solid foundation for refining your prototype and moving toward final production. Thorough documentation not only supports current development but also proves invaluable for future iterations and potential patent applications.

Legal Considerations for Prototypes

Protecting Your Intellectual Property

Intellectual property protection should begin before prototype development starts. File provisional patent applications early in the development process to establish a priority date for your invention. This provides one year of protection while you refine your prototype and assess market potential. Document every aspect of your invention’s development, including sketches, calculations, and test results, dating and signing each entry to establish clear records of invention.

Consider trademark protection for any unique names, logos, or design elements associated with your prototype. While trademarks don’t protect the functional aspects of your invention, they safeguard your branding elements and market identity. Register copyrights for any software, documentation, or creative elements developed alongside your prototype.

Patent Requirements and Prototypes

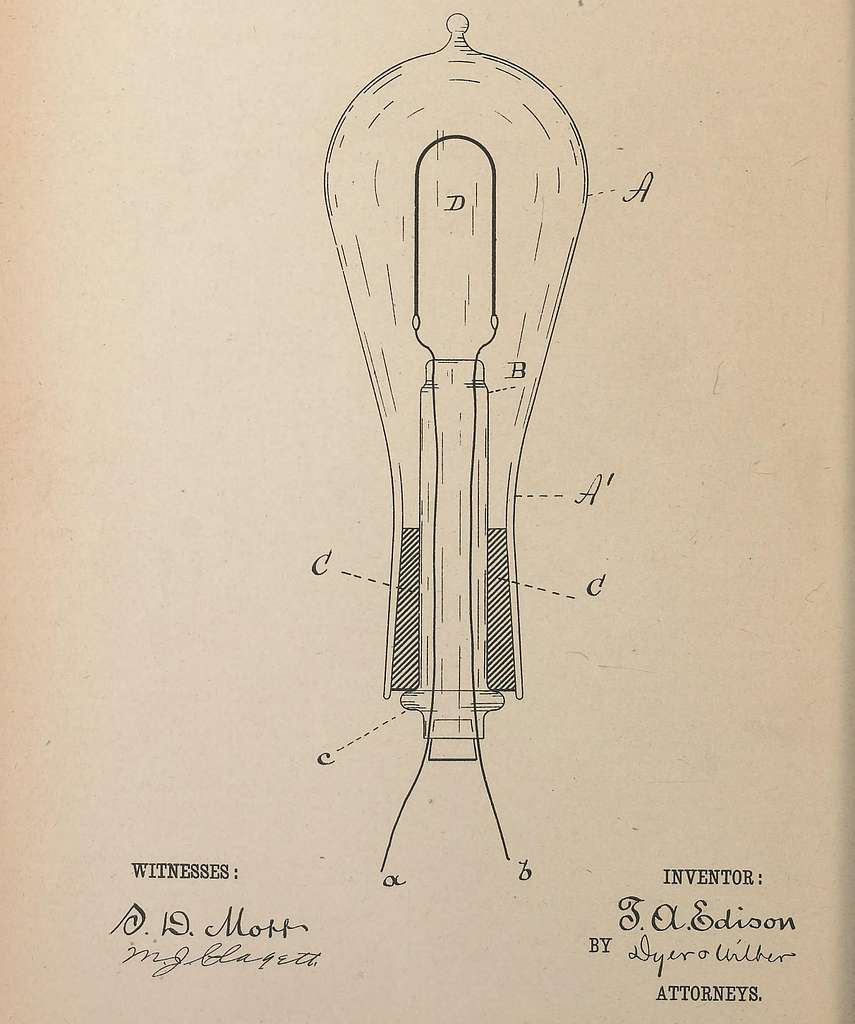

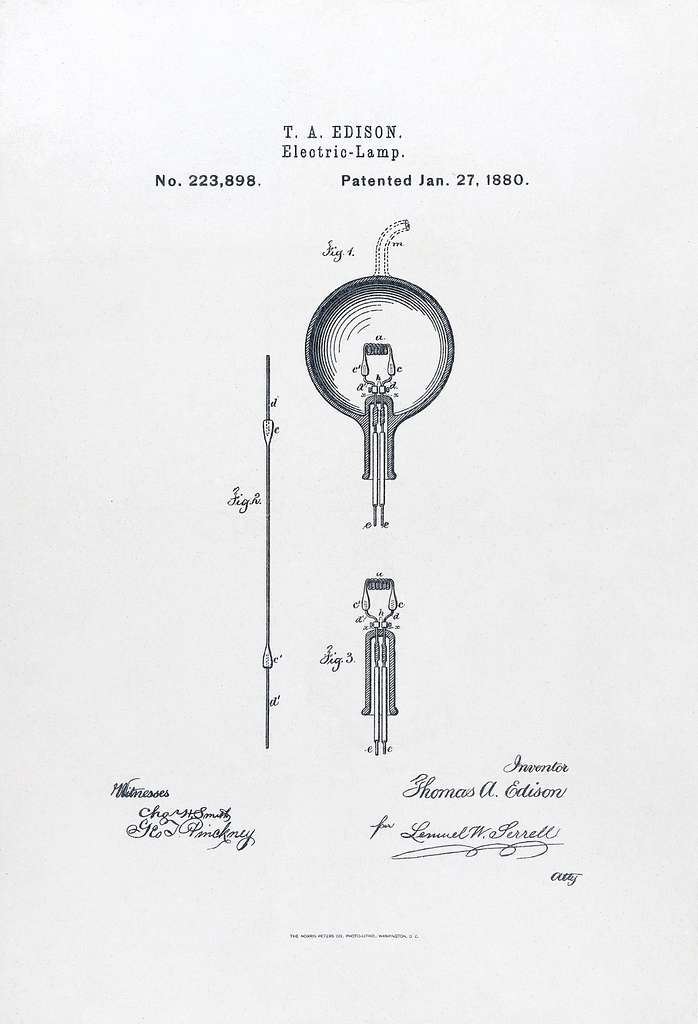

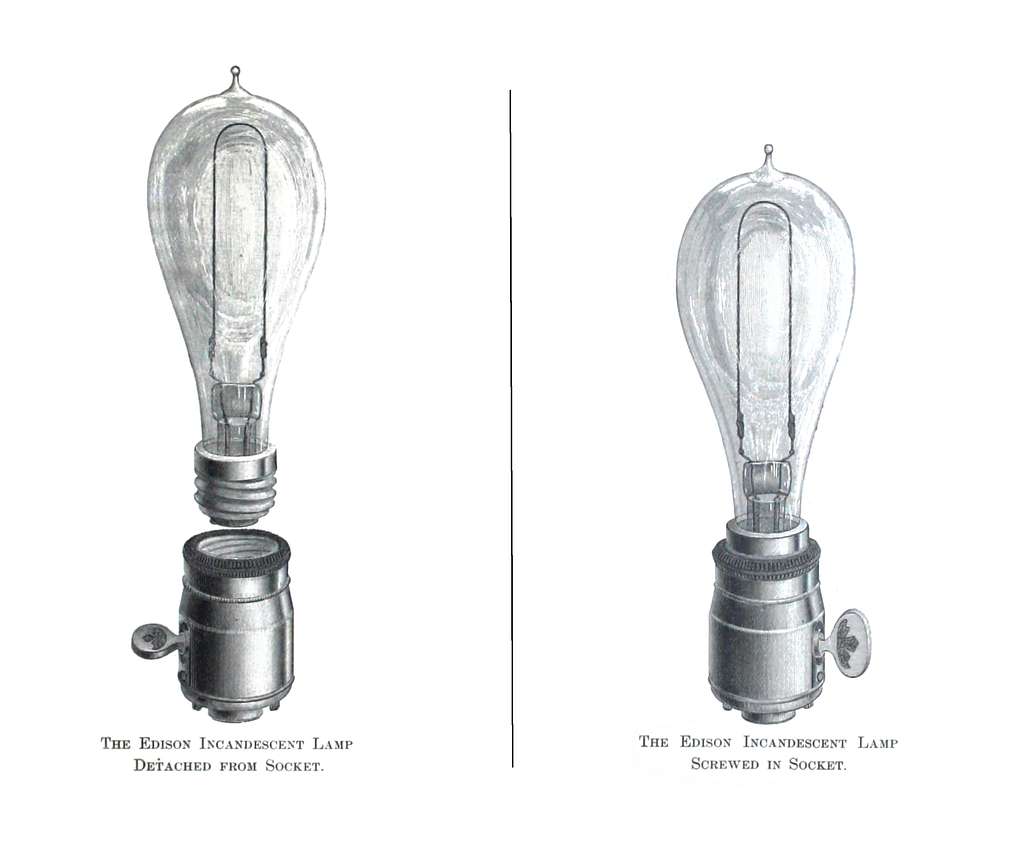

Your prototype plays a crucial role in the patent application process. It demonstrates reduction to practice, proving that your invention works as described. The prototype development process generates detailed documentation needed for patent applications, including technical drawings, specifications, and operational descriptions.

Ensure your prototype documentation includes clear explanations of how your invention solves specific problems or improves upon existing solutions. This information strengthens your patent claims and helps distinguish your invention from prior art. Keep detailed records of any unique features or innovative aspects demonstrated by your prototype, as these often form the basis of patent claims.

Non-Disclosure Agreements

Before sharing your prototype with any outside parties, establish strong confidentiality protections through carefully crafted non-disclosure agreements (NDAs). These agreements should specifically address physical prototypes, technical documentation, and any related intellectual property. Include clear terms about the permitted uses of confidential information and specific prohibitions against reverse engineering or unauthorized reproduction.

Customize NDAs for different types of relationships, whether with potential manufacturers, investors, or testing participants. Include provisions for the return or destruction of confidential materials and prototypes after testing or evaluation. Consider including non-compete clauses when appropriate, particularly when working with potential manufacturing partners.

Working with Prototype Developers

When engaging professional prototype developers, establish clear ownership rights for any improvements or innovations developed during the prototyping process. Create detailed development agreements that specify deliverables, timelines, and quality standards. Include provisions for regular progress reviews and approval stages to maintain control over the development process.

Ensure agreements address the handling of technical documentation, CAD files, and other development materials. Specify requirements for secure storage and transmission of sensitive information. Include provisions for ongoing technical support and modifications, particularly for complex prototypes requiring specialized expertise.

From Prototype to Production

Manufacturing Considerations

The transition from prototype to production requires careful evaluation of manufacturing processes and capabilities. Begin by analyzing your prototype’s design for manufacturability, identifying components that may need redesign for efficient production. Consider material alternatives that maintain functionality while reducing production costs.

Evaluate different manufacturing methods, comparing traditional processes with advanced manufacturing technologies. Assess potential manufacturers based on their technical capabilities, quality standards, and production capacity. Consider geographical factors affecting supply chain logistics and production costs.

Cost Analysis and Optimization

Conduct detailed cost analysis covering materials, labor, equipment, and overhead expenses. Break down costs by component and process to identify opportunities for optimization. Consider the impact of production volume on unit costs, analyzing break-even points and economy of scale benefits.

Evaluate potential cost reductions through design modifications, material substitutions, or process improvements. Consider automation opportunities that might reduce labor costs while maintaining quality standards. Analyze the financial impact of inventory management and storage requirements.

Scaling Up Production

Develop a phased approach to production scaling, starting with pilot runs to validate manufacturing processes. Create detailed production plans addressing equipment requirements, workflow optimization, and quality control procedures. Establish realistic timelines for scaling production while maintaining product quality and consistency.

Consider the impact of increased production on supply chain management and inventory control. Develop relationships with multiple suppliers to ensure stable material availability. Create contingency plans for potential production disruptions or supply chain issues.

Quality Control Implementation

Establish comprehensive quality control systems before beginning full-scale production. Develop detailed quality standards and testing procedures for both components and finished products. Create inspection protocols for different production stages, including incoming materials, in-process checks, and final product testing.

Implement statistical process control methods to monitor production quality and identify potential issues early. Develop documentation systems for tracking quality metrics and production data. Create procedures for handling non-conforming products and implementing corrective actions.

Train production staff on quality requirements and testing procedures. Establish clear communication channels for reporting quality issues and implementing improvements. Develop systems for regular quality audits and continuous improvement initiatives.

Consider certification requirements relevant to your product category, such as ISO standards or industry-specific certifications. Create documentation systems supporting certification maintenance and compliance verification. Establish procedures for regular review and updates of quality control processes.

This systematic approach to quality control helps ensure consistent product quality while identifying opportunities for process improvement and cost reduction. Regular review and updating of quality control procedures helps maintain high standards throughout the production scaling process.

Marketing Your Invention with Prototypes

Using Prototypes for Presentations

Effective prototype presentations require careful preparation and staging. Create a structured demonstration that highlights key features while telling a compelling story about your invention’s value. Begin with a brief overview of the problem your invention solves, then use your prototype to demonstrate the solution in action.

Develop a consistent presentation format that works for different audiences. Practice handling your prototype smoothly during demonstrations, anticipating common questions and preparing clear, concise answers. Keep backup components or a spare prototype available for high-stakes presentations to handle unexpected issues.

Consider the presentation environment when planning demonstrations. Test lighting conditions, space requirements, and any technical needs beforehand. Prepare visual aids that complement your prototype demonstration, such as charts showing performance data or comparison with existing solutions.

Creating Demo Videos

Professional demo videos showcase your prototype’s functionality while reaching a broader audience. Start with a clear storyboard that outlines key demonstration points and visual sequences. Use high-quality lighting and multiple camera angles to capture important details and operations.

Include both overview shots and detailed close-ups highlighting specific features. Demonstrate real-world applications and benefits rather than just technical operations. Consider adding graphics or animations to explain internal mechanisms or complex features that aren’t visible externally.

Create different versions of your demo video for various purposes. Develop shorter versions for social media and initial introductions, while maintaining longer, detailed versions for serious investors or technical audiences.

Trade Show Displays

Trade show presentations require special consideration of booth layout and demonstration space. Design your display to draw attention while facilitating easy prototype demonstrations. Create clear signage explaining key benefits and features that visitors can understand at a glance.

Develop an efficient demonstration routine that works in crowded trade show environments. Train booth staff thoroughly on prototype operation and key selling points. Prepare handouts with technical specifications and contact information for interested parties.

Consider the logistics of transporting and setting up your prototype at trade shows. Design specialized packaging or cases for safe transport. Have backup components or repair tools available to handle any issues during the show.

Attracting Investors

When presenting to investors, focus on demonstrating market potential and scalability. Prepare detailed documentation including market analysis, production costs, and projected returns. Use your prototype to demonstrate key competitive advantages and barriers to entry.

Create a comprehensive pitch deck that complements your prototype demonstration. Include clear financial projections and funding requirements. Be prepared to discuss manufacturing plans, scaling strategies, and intellectual property protection.

Maintain professional presentation materials including business cards, brochures, and technical specifications. Follow up promptly with additional information requested during presentations. Keep detailed records of all investor interactions and feedback.

Common Prototype Development Mistakes

Design Oversights

One of the most common mistakes is rushing through the design phase without thorough analysis. Take time to fully understand user requirements and environmental conditions affecting your invention. Consider maintenance needs and repair access during initial design rather than addressing these as afterthoughts.

Many inventors overlook the importance of thermal management, material fatigue, or environmental factors. Conduct thorough analysis of operating conditions and potential failure modes during design. Include safety features and fail-safes in initial designs rather than adding them later.

Material Selection Errors

Poor material choices often result from focusing solely on initial prototyping without considering production requirements. Research material properties thoroughly, including chemical resistance, UV stability, and aging characteristics. Consider how materials will perform under various environmental conditions and over extended use.

Account for material interactions, including galvanic corrosion between different metals or chemical compatibility issues. Test materials under actual operating conditions rather than relying solely on published specifications. Consider the impact of material choices on manufacturing costs and processes.

Cost Management Issues

Underestimating development costs is a frequent problem in prototype development. Create detailed budgets including all components, tools, and testing equipment needed. Account for multiple iterations and potential failures in your budget planning.

Avoid cutting corners on critical components or testing procedures to save money. Instead, look for cost savings in non-critical areas or through efficient project management. Maintain detailed cost records to inform future development projects and production planning.

Timeline Problems

Unrealistic development timelines often lead to rushed testing and overlooked issues. Create detailed project schedules including time for design reviews, testing, and iterations. Account for supplier lead times and potential delays in material or component availability.

Build in buffer time for unexpected challenges and design changes. Consider seasonal factors that might affect testing or demonstration schedules. Maintain regular progress reviews to identify and address potential delays early in the development process.

Allow adequate time for regulatory compliance testing or certification if required for your product category. Plan for documentation and record-keeping activities throughout the development process rather than trying to reconstruct information later.

Resources for Prototype Development

Finding Professional Help

Professional assistance can significantly accelerate prototype development and avoid costly mistakes. Start by researching industrial design firms and prototype development companies that specialize in your type of invention. Examine their portfolios, client testimonials, and past success stories to ensure they have relevant experience.

Engineering consultants offer specialized expertise for complex technical challenges. Look for professionals with experience in your specific field, whether it’s mechanical engineering, electronics, software development, or materials science. Professional organizations and industry associations often maintain directories of qualified consultants and firms.

Contract manufacturers can provide valuable insights into production feasibility while helping develop manufacturing-ready prototypes. Many offer design for manufacturing (DFM) services alongside prototyping capabilities. Establish relationships with multiple service providers to ensure access to different capabilities and maintain competitive pricing.

Build relationships with patent attorneys experienced in your industry. They can provide guidance on protecting your intellectual property throughout the development process. Many offer initial consultations to assess your needs and outline protection strategies.

Prototype Development Tools

Digital design tools form the foundation of modern prototype development. Computer-Aided Design (CAD) software ranges from free options like FreeCAD and TinkerCAD to professional solutions like SolidWorks and Fusion 360. Consider online training courses to master these essential tools.

Simulation software helps validate designs before physical prototyping. Tools like ANSYS or COMSOL can analyze structural integrity, fluid dynamics, thermal performance, and other critical factors. While expensive, these tools often save money by reducing physical prototype iterations.

Project management tools help track development progress and manage resources. Options range from simple task management apps to comprehensive product lifecycle management (PLM) systems. Choose tools that match your project’s complexity and team size.

Testing and measurement equipment varies by project needs. Basic tools might include calipers, multimeters, and data loggers, while advanced projects might require specialized testing apparatus. Consider renting expensive equipment for short-term needs rather than purchasing.

Funding Sources

Government grants often support innovation and prototype development. Research federal, state, and local grant programs targeting small businesses and inventors. Small Business Innovation Research (SBIR) and Small Business Technology Transfer (STTR) programs provide significant funding for qualifying projects.

Crowdfunding platforms like Kickstarter and Indiegogo can provide both funding and market validation. Successful campaigns require careful preparation, including compelling presentations and realistic production plans. Consider the platform’s audience and requirements when planning your campaign.

Angel investors and venture capital firms offer funding alongside business expertise. Prepare comprehensive business plans and market analysis before approaching investors. Network through startup events and entrepreneurship organizations to build relationships with potential investors.

Universities and research institutions often provide access to equipment and expertise through partnership programs. Many operate innovation centers or entrepreneurship programs supporting prototype development. These partnerships can provide both technical resources and potential funding opportunities.

Educational Resources

Online learning platforms offer courses covering all aspects of prototype development. Platforms like Coursera, Udemy, and LinkedIn Learning provide structured training in design, engineering, and manufacturing processes. Look for courses teaching specific skills needed for your project.

Technical communities and forums provide valuable peer support and problem-solving resources. Platforms like GrabCAD, Engineering.com, and specialized LinkedIn groups connect inventors with experienced professionals. Participate actively to build relationships and gain insights from others’ experiences.

Industry publications and journals keep you informed about new technologies and methods. Subscribe to relevant technical magazines and online newsletters. Many provide case studies and detailed technical articles useful for prototype development.

Maker spaces and innovation centers offer hands-on learning opportunities alongside access to tools and equipment. These facilities often provide training workshops and networking events. Members can learn from experienced makers while accessing equipment that would be costly to purchase individually.

Trade associations and professional organizations provide valuable educational resources and networking opportunities. Many offer conferences, workshops, and certification programs. Membership often includes access to technical libraries, standards documents, and expert consultations.

Local business development centers and Small Business Administration (SBA) offices provide entrepreneurship training and resources. They often offer workshops on business planning, funding strategies, and manufacturing. These organizations can connect you with mentors and advisors experienced in product development.

Remember to regularly update your knowledge as technology and methods evolve. Stay connected with professional networks and continue learning throughout your development process. Document lessons learned to build your own knowledge base for future projects.

Surely one day they’re going to invent a way to heal cuts and wounds significantly faster. Some kind of material that you just rub onto a wound (or a super-plaster of sorts), and within minutes the wound is healed and there are no scars.

Surely one day they’re going to invent a way to heal cuts and wounds significantly faster. Some kind of material that you just rub onto a wound (or a super-plaster of sorts), and within minutes the wound is healed and there are no scars. Here’s one that we all can hopefully agree upon. We’re living in the twenty-first century, and yet there is still no cure for the common cold. A cold brings you down: it makes you snivel and sniff and all congested for days.

Here’s one that we all can hopefully agree upon. We’re living in the twenty-first century, and yet there is still no cure for the common cold. A cold brings you down: it makes you snivel and sniff and all congested for days. So you’re chewing your gum. Chewing and chewing. You’re really enjoying the flavor: it’s fresh, pungent, rich and sometimes even a bit spicy. And after a few minutes it’s gone, evaporated. You might as well be chewing on a piece of rubber; it tastes just the same. That’s why we say that someone should invent infinitely flavorsome chewing gum.

So you’re chewing your gum. Chewing and chewing. You’re really enjoying the flavor: it’s fresh, pungent, rich and sometimes even a bit spicy. And after a few minutes it’s gone, evaporated. You might as well be chewing on a piece of rubber; it tastes just the same. That’s why we say that someone should invent infinitely flavorsome chewing gum. One of the most painful things in the world is your mobile phone going dead. Especially when you’re out, with no access to a charger, and you need to receive a text or make a phone call. And smartphones are particularly bad at battery life. The problem is the very concept of the battery that requires an external electric power source to charge it.

One of the most painful things in the world is your mobile phone going dead. Especially when you’re out, with no access to a charger, and you need to receive a text or make a phone call. And smartphones are particularly bad at battery life. The problem is the very concept of the battery that requires an external electric power source to charge it. Not sure how well this one would fly; some people love bragging about how drunk they got the night before. But others would love to enjoy alcohol without feeling incredibly hung-over the next day.

Not sure how well this one would fly; some people love bragging about how drunk they got the night before. But others would love to enjoy alcohol without feeling incredibly hung-over the next day. Ok I’m not sure how possible this is. But that’s the whole point of being inventive and creative: it’s to go beyond the possible. So this idea is a means to prevent the need to have a cumbersome and heavy oxygen tank with you when you dive in the ocean. Besides that, there’s always the worry that it might run out.

Ok I’m not sure how possible this is. But that’s the whole point of being inventive and creative: it’s to go beyond the possible. So this idea is a means to prevent the need to have a cumbersome and heavy oxygen tank with you when you dive in the ocean. Besides that, there’s always the worry that it might run out.